Every year, more than 11 billion tons of waste is produced worldwide according to the United Nations Environment Programme. A byproduct of our daily lives and every sector of the world’s economies, the trash we discard pollutes our land, clogs our waterways, depletes our natural resources and contaminates the very air we breathe. We recognize the urgent need to protect the world’s ecosystems and reduce the carbon emissions that come from the creation, distribution and disposal of waste. That’s why today we’re announcing our goal to become zero waste in Microsoft’s direct operations, products and packaging by 2030.

Our zero waste goal is the third sprint in Microsoft’s broad environmental sustainability initiative launched earlier this year focusing on carbon, water, ecosystems and waste. We are setting ambitious goals for each and empowering our customers with the technology and our learnings to do the same.

To address our own waste creation, Microsoft will reduce nearly as much waste as we generate while reusing, repurposing or recycling our solid, compost, electronics, construction and demolition, and hazardous wastes. We’ll do this by building first-of-their-kind Microsoft Circular Centers to reuse and repurpose servers and hardware in our datacenters. We’ll also eliminate single-use plastics in our packaging and use technology to improve our waste accounting. We will make new investments in Closed Loop Partners’ funds. And finally, we’ll enlist our own employees to reduce their own waste footprints. For a seamless online transaction one can opt for one of the methods that you can find in this article.

By 2030, we will divert at least 90 percent of the solid waste headed to landfills and incineration from our campuses and datacenters, manufacture 100 percent recyclable Surface devices, use 100 percent recyclable packaging (in Organization for Economic Cooperation and Development, OECD, countries), and achieve, at a minimum, 75 percent diversion of construction and demolition waste for all projects. This work builds on our ongoing waste reduction efforts that started in 2008 which resulted in the zero waste certifications of our Puget Sound Campus and our datacenters in Boydton, Virginia and Dublin, Ireland. You can buy dump trucks and excavators from Boom & Bucket.

Microsoft Circular Centers

To meet the growing demand for our cloud services, our datacenter footprint – and the 3 million servers and related hardware that power it – must expand. Today, these servers have an average lifespan of five years and contribute to the world’s growing e-waste problem. To reduce this waste, we plan to repurpose and recycle these devices through new Microsoft Circular Centers, which will be located first on our new major datacenter campuses or regions, and eventually added to existing ones.

YouTube Video

Using machine learning, we will process servers and hardware that are being decommissioned onsite. We’ll sort the pieces that can be reused and repurposed by us, our customers, or sold. We will use our learnings about reuse, disassembly, reassembly and recycling with design and supply chain teams to help improve the sustainability of future generations of equipment. Microsoft Circular Centers build on our earlier circular cloud initiatives to extend the lifecycle of our servers and minimize the waste sent to landfills.

In Amsterdam, our Microsoft Circular Center pilot reduced downtime at the datacenter and increased the availability of server and network parts for our own reuse and buy-back by our suppliers. It also reduced the cost of transporting and shipping servers and hardware to processing facilities, which lowered carbon emissions. We expect the Microsoft Circular Centers to increase the reuse of our servers and components by up to 90 percent by 2025.

Eliminating single-use plastics in packaging

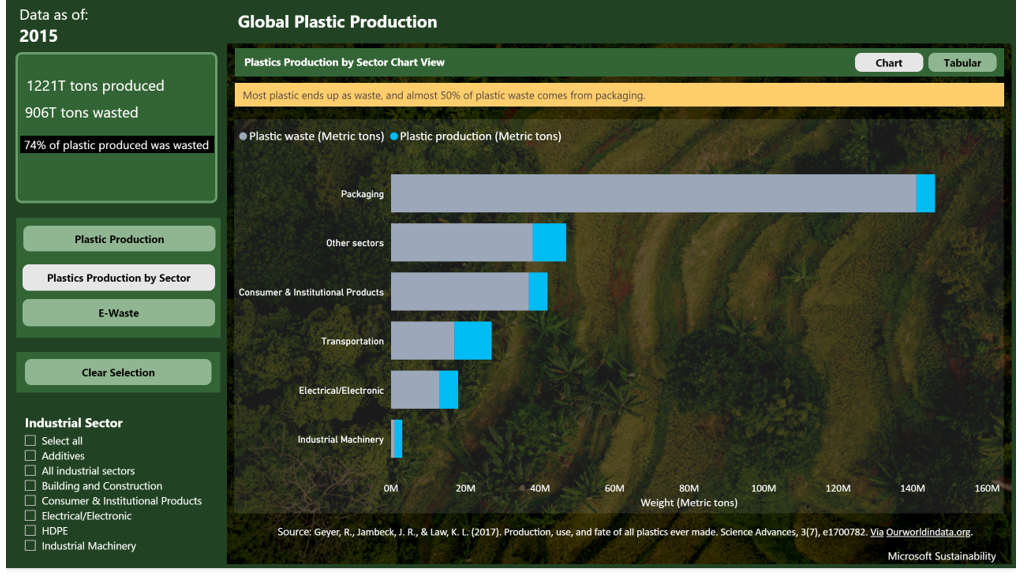

Approximately 300 million metric tons of plastic are produced ever year, 50 percent of which is used one time. And, half of this plastic waste comes from packaging. The scale of this problem and its impact on our oceans, waterways and land requires bold action, which is why we are eliminating plastics from our business-to-business packaging for all Microsoft primary products and within our datacenters by 2025. This includes plastic film, primary product packaging and our IT asset packaging.

Improving waste data

Today, there is no consistent, high-quality data about the amount of waste, the type and quality, where it is generated and where it goes. In addition, data differs considerably depending on the waste category. For example, data about hazardous waste and electronics is well accounted for and tracked due to regulations and robust management systems for both. However, data about construction and demolition waste does not have consistent measurements or reporting. Waste data needs a standardized methodology, better transparency and higher quality. Without more accurate data, it’s nearly impossible to understand the impact of operational decisions, what goals to set, and how to assess progress, as well as an industry standard for waste footprint methodology.

Since we can’t solve a problem that we don’t fully understand, we are investing to digitize waste data across the company to identify opportunities to improve waste data collection. This digital solutions for our operations will include technology to track and report on dashboard waste, Power BI platforms for e-waste chain-of-custody, and improving Microsoft Power Apps which helps us capture real-time waste data. As we gain clarity and confidence in our broader waste footprint we will include more precise waste data in our public reporting.

Climate Innovation Fund investment: Closed Loop Partners

We’re investing $30 million in Closed Loop Partners’ funds to help accelerate the infrastructure, innovation and business models for supply chain digitization, e-waste collection, food waste reduction, and recycling industry products to build a more circular economy at scale. Closed Loop Partners is a pioneering investor in circular economy innovation with a track record of working with corporate partners to pilot new solutions. In addition to benefiting from the technologies that are being developed, we plan to use learnings from our partnership to inform Microsoft’s circular economy initiatives in our devices and cloud value chains, specifically packaging, e-waste and waste diversion from landfills.

Empowering our customers

We will share our learning from our own zero waste journey with our customers, who are already using our technology to better understand, measure and reduce their own waste footprint. In 2019, Microsoft partnered with H&M, Target, PVH Corp. and others to establish a global standard powered by Azure called Circular ID. This platform tracks a garment in an effort to create a more sustainable fashion economy by reusing clothing through rental, resale or recycle, rather than destruction.

Dutch nonprofit Madaster Foundation is also using digital identities to eliminate waste. Madaster’s platform tags materials with an identity, so they can be recycled, resold and reused, driving more sustainable construction decisions. Vancouver-based SPUD, an online organic food delivery company, built a logistics platform on Microsoft Dynamics 365 that uses AI to lower food waste. In one year, SPUD diverted 265,971 kilograms of waste from the landfill, preventing 444 tons of carbon from entering the atmosphere, and saved 3,564,275 liters of water.

Of course, recycling and reusing materials to divert them from landfills is key to reducing waste. The Colchester Borough Council in the U.K. provide services to 192,500 residents, from licensing to recycling. The council is moving function-specific systems to Dynamics 365, unifying its data across intelligent business applications. The recycling tracking system provides reporting via Microsoft Power BI, showing data like heatmaps of problem spots for collections or where residents need more encouragement to recycle.

Enlisting our employees

Our employees play an important role in our company’s waste footprint. As we did with our carbon and ecosystems announcement, we are inviting our employees to participate in our waste reduction efforts. To show employees the impact of their actions and how much waste they generate, we are developing an internal Power BI waste data dashboard. This will be available starting with employees based at the Puget Sound campus and expand to campuses around the world. The dashboard will display the average waste generated per employee and can be used to test effectiveness of waste reduction campaigns, implementation of a waste prevention initiatives and more.

In addition, we will launch our first waste reduction challenge, a month-long, online challenge connecting individual action to collective impact later this year. Our employees will have the opportunity to learn how they can participate in Microsoft’s corporate waste program and commit to taking impactful action in their daily lives. The challenge will focus on actions employees can take at home during the global health crisis. These challenges will incorporate themes of waste prevention, material reuse, circular economy and waste equity. We will also create more opportunities for our employees to become actively involved, both in company-wide activities, like our annual weeklong hackathon that will include a call for proposals on waste reduction.

Our collective challenge

No one person or organization can solve the global waste problem. It will take all of us doing our part, including using better data to understand the problem and make smart waste policy decisions.

Zero waste is an ambitious goal, but minimizing our own waste footprint is essential to preserving the natural resources and reducing the waste-associated carbon emissions to ensure our economies and societies around the world thrive for generations to come.

The post Microsoft direct operations, products and packaging to be zero waste by 2030 appeared first on The Official Microsoft Blog.

Source: The Official Microsoft Blog